The All-in-One Sentinel: How a Computerized Mattress Tester Validates Every Aspect of Sleep Quality

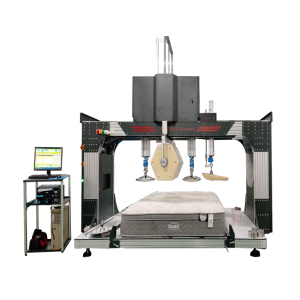

For mattress manufacturers, quality isn’t a single metric—it’s a multi-dimensional promise of durability, support, comfort, and consistency. Navigating separate tests for rolling fatigue, edge integrity, firmness feel, and dimensional accuracy is inefficient and risks data silos. How can you ensure every unit complies with national standards while optimizing your lab’s workflow? The Computerized National Standard Mattress Comprehensive Testing Machine is the engineered solution. This integrated system consolidates four critical GB-standard tests into one automated, computer-controlled platform, transforming subjective quality checks into objective, reportable data. This guide explores how it serves as the central command center for modern mattress quality assurance.

What is a Computerized Mattress Comprehensive Testing Machine?

The Computerized National Standard Mattress Comprehensive Testing Machine is a fully integrated, software-driven testing station engineered to perform a complete battery of mechanical evaluations on a mattress in accordance with national standards (如 GB/T 1952.2, GB/T 26706 等). As the name specifies, it combines four essential test modules into one unified system: 1) Rolling Durability, 2) Edge Compression, 3) Firmness/Hardness Indentation, and 4) Height Dimensional Measurement. The “Computerized” aspect is key: a central computer controls all actuators, collects data from high-precision sensors, and generates unified test reports. This eliminates operator variance and provides a holistic, data-driven view of GB mattress standard compliance and product performance.

The Four Pillars of Testing: Decoding the Integrated Modules

Understanding each module reveals the machine’s comprehensive coverage of real-world use scenarios:

- 1. Mattress Rolling Durability Test: Simulates years of sleep movement. A weighted roller traverses the mattress surface thousands of times, testing internal spring fatigue, foam resilience, and fabric integrity against long-term repetitive loading.

- 2. Edge Compression Strength Test: Evaluates the mattress border’s resistance to sagging. A pressure plate applies force to the side edge, measuring its ability to support weight when sat upon—a critical factor for durability and safety.

- 3. Firmness & Hardness Indentation Test: Quantifies the “feel.” A standardized indenter presses into the mattress surface, measuring the force required to achieve specific depressions. This objective data replaces subjective hand-feel for classifying plush, medium, or firm models.

- 4. Height & Dimensional Measurement: Precisely measures the mattress’s overall height and thickness under no-load and loaded conditions, ensuring it meets specified dimensions and thickness retention claims.

How the Integrated System Works: From Sample to Certified Report

The operation of this mattress rolling test machine and its sister modules is a seamless, automated workflow:

- Unified Setup & Registration: A single mattress sample is placed on the test platform. Its ID is entered into the computer system once.

- Sequential Automated Testing: The operator selects the full test suite. The machine automatically executes tests in sequence (e.g., Height -> Firmness -> Edge -> Rolling), repositioning actuators and sensors as needed.

- Precise Data Acquisition: Each module uses dedicated load cells, displacement sensors, and linear actuators, all synchronized by the central computer to collect accurate force, distance, and cycle count data.

- Centralized Data Analysis & Reporting: All data streams into one software. It analyzes results against preset GB tolerance limits, flags failures, and generates a single, comprehensive compliance certificate covering all four aspects.

This integration is the ultimate tool for mattress firmness and hardness tester accuracy and efficiency.

The Strategic Business Case for an All-in-One Tester

Investing in this comprehensive system delivers transformative benefits far beyond the sum of its parts:

- Maximize Laboratory Efficiency & ROI: One machine, one operator, and one software license replace four separate setups, drastically saving space, capital cost, and labor time.

- Ensure Unambiguous GB Standard Compliance: By using one calibrated system for all required tests, you eliminate inter-equipment variation and provide auditors with a single, irrefutable source of compliance data.

- Gain Holistic Product Insight: Correlate data across tests (e.g., does firmness change after rolling fatigue? Does edge strength correlate with height loss?) to gain deeper R&D insights and optimize product design.

- Build a Brand on Verifiable Quality: Market your mattresses with confidence, backed by a complete computer-generated test report that proves durability, safety, comfort, and consistency in one document.

Key Selection Criteria for Your Comprehensive Testing Solution

When evaluating a Computerized National Standard Mattress Comprehensive Testing Machine, verify these critical capabilities:

- Full GB Standard Coverage: Ensure all four test modules (Rolling, Edge, Firmness, Height) are included and configured to meet the latest versions of the relevant Chinese national standards.

- True Software Integration: The software must be a unified platform that controls all modules, manages one sample database, and produces combined reports—not four separate programs bolted together.

- Modular Robustness & Precision: Each physical module (e.g., the rolling carriage, edge press, indentation head) must be built to industrial standards for accuracy and long-term durability under high-cycle testing.

- Ease of Use & Automation: Look for features like motorized adjustments, barcode sample tracking, and automated test sequencing to minimize operator training and error.

Conclusion: The Cornerstone of Data-Driven Mattress Manufacturing

In an industry where comfort is king and durability is demanded, the Computerized National Standard Mattress Comprehensive Testing Machine is more than a piece of equipment—it is the foundational pillar of a modern, data-driven manufacturing philosophy. By converging critical testing into a single source of truth, it empowers manufacturers to guarantee quality with unprecedented efficiency and confidence. This investment transcends compliance; it is a commitment to engineering superior sleep products, building unshakable consumer trust, and establishing your brand as a leader defined by proven, comprehensive quality.

Post time: Dec-12-2025