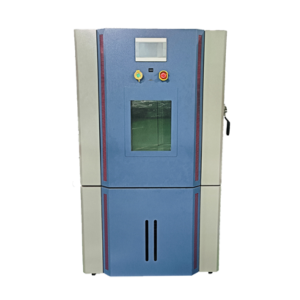

Constant Temperature and Humidity Test Chamber: The Essential Guide to Environmental Reliability Testing

Understanding Environmental Simulation: Why Temperature and Humidity Testing is Critical

In today’s global market, products must perform reliably under diverse environmental conditions. A constant temperature humidity test chamber serves as a vital tool for simulating these conditions in a controlled laboratory setting. By precisely regulating temperature and humidity levels, this equipment allows manufacturers to evaluate how materials and products withstand heat, cold, dryness, and moisture—accelerating years of environmental exposure into days or weeks of testing.

How Constant Temperature Humidity Chambers Work

These sophisticated chambers create stable, repeatable environments through integrated systems. A refrigeration unit controls temperature (both heating and cooling), while a humidification system introduces moisture and a dehumidification system removes it. Advanced microprocessor controllers manage these systems to maintain setpoints with extreme precision, often within ±0.5°C for temperature and ±2.5% RH for humidity.

Core Components and Technology

- Precision Temperature Control System: Utilizes electric heaters and mechanical refrigeration (compressor-based) to achieve wide temperature ranges, typically from -70°C to +150°C.

- Humidity Generation and Control: Employs steam generators, water spray systems, or ultrasonic humidifiers to create moisture, with chilled mirror hygrometers or capacitive sensors for accurate measurement.

- Advanced Programmable Controller: Allows users to create complex test profiles with multiple temperature and humidity steps, ramps, and dwell times.

- Air Circulation System: Ensures uniform distribution of temperature and humidity throughout the test volume, eliminating hot or cold spots.

Comprehensive Testing Capabilities

Modern chambers perform various test protocols to evaluate different aspects of product durability.

1. Temperature and Humidity Resistance Testing

This fundamental test exposes products to constant high temperature and humidity conditions (e.g., 85°C/85% RH) to accelerate aging and identify material weaknesses, corrosion susceptibility, and electrical failures.

2. Thermal Cycling with Humidity

Products undergo repeated transitions between temperature extremes (e.g., -40°C to +125°C) while humidity levels also change. This tests material expansion/contraction, solder joint integrity, and resistance to thermal stress.

3) Damp Heat and Dry Heat Testing

Damp heat tests evaluate product performance in tropical conditions, while dry heat tests simulate desert environments. Both are crucial for validating products for specific geographic markets.

Industry-Specific Applications Across Sectors

Electronics, Electrical and Telecommunications

Essential for testing circuit boards, semiconductors, connectors, and consumer electronics. Chambers identify failures from moisture ingress, thermal expansion mismatches, and electrochemical migration.

Automotive Components

Validates reliability of sensors, control units, displays, and interior materials under conditions ranging from frozen winters to hot, humid summers.

Plastic and Polymer Products

Evaluates how plastics, rubbers, and composites respond to environmental stress—checking for dimensional changes, cracking, stiffness variations, and color fading.

Aerospace and Defense

Tests avionics, materials, and components to extreme military and aerospace standards (like MIL-STD-810), ensuring operation from high-altitude cold to engine compartment heat.

Pharmaceutical and Medical Devices

Verifies stability of drugs, vaccines, and medical equipment under various storage conditions, crucial for compliance with regulatory requirements like ICH guidelines.

Selecting the Right Test Chamber: Key Considerations

Choosing appropriate equipment requires careful evaluation of several factors:

- Temperature and Humidity Range: Match to your product’s worst-case deployment environments and applicable test standards.

- Chamber Size and Capacity: Ensure interior dimensions accommodate your largest products with adequate space for air circulation.

- Rate of Change: Faster temperature ramping (e.g., 10°C/minute vs 3°C/minute) reduces test time but increases equipment cost.

- Control Precision and Uniformity: Critical for reproducible test results and compliance with stringent standards.

- Data Recording and Connectivity: Look for chambers with comprehensive data logging, remote monitoring, and network capabilities.

Operational Best Practices and Maintenance

Proper operation extends chamber life and ensures accurate results:

- Proper Loading: Avoid blocking air vents; use racks that promote airflow around test specimens.

- Regular Calibration: Schedule periodic calibration of temperature and humidity sensors using NIST-traceable standards.

- Preventive Maintenance: Regularly clean humidification water systems, inspect door seals, clean condenser coils, and check refrigerant levels.

- Water Quality Management: Use deionized or distilled water in humidification systems to prevent mineral buildup and contamination.

Compliance with International Test Standards

Constant temperature humidity chambers help manufacturers comply with numerous industry standards:

- IEC 60068-2-1/2/30/78: Basic environmental test procedures for electronic products

- ISO 16750-4: Road vehicles – Environmental conditions for electrical/electronic equipment

- JEDEC JESD22-A101: Steady-state temperature humidity bias life test

- MIL-STD-810: Environmental engineering considerations for military equipment

- ASTM D2126: Standard test method for response of rigid plastics to temperature and humidity

The Future of Environmental Testing Technology

Advancements are making chambers smarter and more capable. Trends include integration with IoT for remote monitoring and predictive maintenance, improved energy efficiency through better insulation and compressor technology, faster thermal transition rates for accelerated testing, and enhanced software for easier test programming and data analysis.

Conclusion: Building Confidence Through Environmental Validation

A constant temperature humidity test chamber is more than just a quality control tool—it’s an essential instrument for product development and reliability assurance. By subjecting products to controlled environmental stresses before market release, manufacturers can identify failure modes, improve designs, reduce warranty claims, and build brand reputation for durability. In an increasingly quality-conscious global marketplace, comprehensive environmental testing has become not just an option, but a fundamental requirement for product success across virtually all manufacturing sectors.

Post time: Jan-09-2026