Beyond the Edge: How a 5-in-1 Strength Tester Becomes Your Packaging Lab’s Command Center

In the competitive world of packaging, every gram of material counts, and every box must be strong enough to protect its contents without being over-engineered. Relying on separate, single-function machines for ring pressure, flat crush, edge crush, adhesion, and general compression is costly, space-inefficient, and risks data inconsistency. How can quality labs achieve comprehensive, reliable strength analysis with unmatched efficiency? The answer is the modern Edge Crush Strength Testing Machine. Far more than its name suggests, this advanced instrument is a fully integrated packaging strength analyzer, capable of performing five critical tests with a single, high-precision system. This guide explores how it centralizes your quality control and drives smarter packaging decisions.

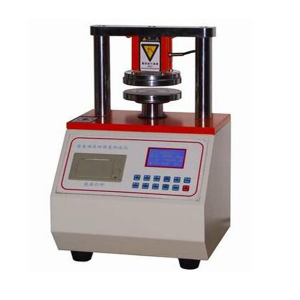

What is an Edge Crush Strength Testing Machine?

An Edge Crush Strength Testing Machine is a sophisticated, digitally-controlled universal testing platform specifically engineered for the paper and corrugated packaging industry. While its name highlights the pivotal Edge Crush Test (ECT), its true power lies in versatility. As your product description confirms, it integrates tooling and software to perform five distinct tests: Ring Crush (RCT), Flat Crush (FCT), Edge Crush (ECT), Pin Adhesion (PAT), and General Compression (CMT). By utilizing a high-accuracy load cell and intelligent software, it transforms physical force into precise digital data, making it the definitive core of any modern packaging quality control laboratory seeking efficiency and data integrity.

The Quintessential Five: A Test for Every Strength Dimension

Understanding each test function reveals the machine’s comprehensive coverage of packaging performance:

- Edge Crush Test (ECT): Measures the edgewise compressive strength of corrugated board, directly predicting a box’s top-to-bottom stacking capability.

- Ring Crush Test (RCT): Evaluates the inherent compression resistance of paperboard liner, a key indicator of raw material quality.

Flat Crush Test (FCT): Assesses the resistance of corrugated flute to crushing, indicating the board’s rigidity and cushioning properties.

- Pin Adhesion Test (PAT): Quantifies the bonding strength between the corrugated medium and the liner sheets, crucial for delamination resistance.

- General Compression Test (CMT): A versatile mode for testing finished boxes, protective packaging, or other components under compressive load.

Technology in Focus: Precision from Sensor to Screen

The reliability of this corrugated board tester hinges on its advanced sensing and analysis system, as outlined in your description:

- High-Precision Load Cell: The heart of the system. This sensor detects minute forces with exceptional accuracy, ensuring every newton or pound of pressure is captured faithfully.

- Intelligent Software Analytics: Raw sensor data is processed and “parsed” by dedicated software. This transforms analog signals into clear, digital readouts of peak strength, averages, and statistical data.

- Interchangeable Test Fixtures: The key to multi-functionality. Quick-change fixtures—compression plates, ring crush units, edge crush guides, and peel/adhesion jigs—enable rapid switching between test types.

- Digital Display & Data Export: Results are shown clearly on a digital screen and can typically be exported for reporting, SPC (Statistical Process Control) analysis, and compliance records.

The Testing Workflow: From Sample to Actionable Data

Operating this integrated system streamlines the testing process for all five methods:

- Fixture Selection & Installation: Choose and install the correct fixture for the desired test (e.g., ECT guides, RCT ring, PAT pins).

- Sample Preparation & Mounting: Prepare the standardized sample (strip of board, ring of liner, finished box corner) and mount it securely in the fixture.

- Test Initiation: Start the test via the control interface. The machine’s crosshead applies controlled, increasing pressure to the sample.

- Automatic Data Capture & Analysis: The system automatically detects the peak crushing or adhesive force, and the software calculates and displays the result (in kPa, N, or lbf).

- Reporting & Decision Making: Use the data to approve materials, adjust manufacturing processes, certify shipments, or benchmark against box compression strength requirements.

The Business Case: Why a 5-in-1 Tester is a Strategic Investment

Consolidating testing capabilities into one ECT tester platform delivers transformative benefits:

- Maximize Laboratory ROI & Space: Eliminates the capital and maintenance costs of multiple single-purpose machines, while freeing up valuable lab floor space.

- Ensure Unparalleled Data Consistency: Using one calibrated sensor and software system for all five tests guarantees that results are directly comparable and free from inter-instrument variation.

- Dramatically Improve Testing Efficiency: Rapid fixture changes allow a single operator to conduct a full battery of tests in succession, drastically increasing lab throughput.

- Empower Comprehensive Quality Intelligence: Correlating data from ECT, FCT, and PAT on the same sample provides a holistic view of board quality, enabling superior problem diagnosis and material optimization.

Key Selection Criteria for Your Integrated Lab Solution

When choosing your Edge Crush Strength Testing Machine, verify these critical capabilities:

- True 5-in-1 Functionality: Confirm that the standard package includes all necessary fixtures and software modules for RCT, FCT, ECT, PAT, and CMT.

- Accuracy & Compliance: Ensure the machine meets the accuracy requirements of international standards like TAPPI T 839 (ECT), ISO 3037, and others relevant to your markets.

- Ease of Use & Fixture Changeover: The system should be designed for intuitive operation, with fixtures that are robust yet easy to swap quickly and reliably.

- Software & Data Management: The software should not only display results but also allow for user management, batch testing, and easy export of data for traceability.

Conclusion: The Unified Standard for Packaging Confidence

In an industry where strength is quantified and cost is scrutinized, the integrated Edge Crush Strength Testing Machine represents the future of packaging quality assurance. It transcends the limitation of single-metric testing, providing a unified platform to understand, control, and optimize every dimension of paper and board performance. Investing in this comprehensive solution is not merely about purchasing a tester; it’s about establishing a single source of truth for your packaging strength data, empowering your team to make smarter, faster, and more confident decisions that protect your products and your profit margins.

Post time: Dec-03-2025