Introduction: Why “Testing” is Your Secret Weapon for Market Dominance

In the competitive world of furniture manufacturing, the line between a premium brand and a commodity product is often drawn not in the design studio, but in the testing lab. While aesthetics attract, it is verifiable quality and proven durability that build lasting customer trust and market dominance. The common pain points—costly customer complaints, high return rates, brand reputation damage, and barriers to entering lucrative markets like North America and Europe—can all be mitigated with a strategic approach to furniture quality control. This article presents three powerful furniture testing case studies that demonstrate how moving beyond basic compliance to a culture of rigorous validation directly translates into higher sales, stronger brands, and access to global markets.

Case Study 1: How a Sofa Manufacturer Slashed Returns by 30% with Fabric & Frame Testing

A mid-sized upholstery manufacturer specializing in residential sofas faced a critical challenge: nearly 15% of their products were being returned within the first year. The primary complaints were fabric pilling and annoying frame squeaks, eroding customer trust and profitability.

The Problem: Customer Complaints on Fabric Pilling and Frame Noise

Informal, pass/fail quality checks were insufficient. They lacked data to pinpoint whether failures were due to inferior fabric, weak joint construction, or poor assembly. This led to disputes with suppliers and inconsistent product performance.

The Testing Solution: A Dual-Pronged Approach

The company implemented a data-driven testing regime:

- Fabric Durability Tests: Every fabric batch was subjected to a Martindale abrasion test (a standard for simulating long-term wear). Instead of just meeting a minimum threshold, they set a higher internal standard of 40,000 cycles for premium lines. Rub tests for colorfastness were also standardized.

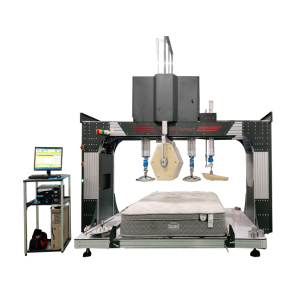

- Frame Fatigue Testing: They invested in a durability testing machine to simulate a decade of use in weeks. Protocols included a seat drop test (simulating repeated sitting) and a backrest load test (simulating forceful leaning), monitoring for joint integrity and noise.

The ROI: Numbers That Matter

Within eight months, the return rate attributed to fabric and frame failure dropped by 30%. Supplier quality improved because contracts were now based on objective test data. Furthermore, having a documented furniture durability test protocol helped them win a contract with a hotel chain that required proven product lifespan data.

Case Study 2: Passing BIFMA Certification: An Office Chair’s Path to Global Acceptance

A growing office furniture maker aspired to break into the lucrative North American contract market. They quickly learned that BIFMA certification was not just a badge but a non-negotiable requirement for specifiers and large corporations.

The Challenge: Breaking into the Contract Furniture Market

Attempting to self-verify with in-house tools failed to produce the internationally recognized reports needed. The path to certification seemed complex and fraught with risk of failure.

The Testing Protocol: Key Tests That Make or Break Certification

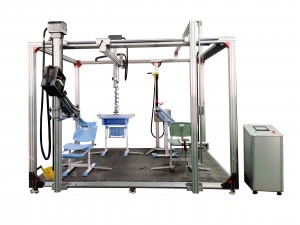

Partnering with a lab equipped for BIFMA testing, they focused on the most critical tests for their task chair:

- Drop Test: A 225-pound weight was dropped onto the seat from a height to validate the shock absorption and structural integrity of the chair leg and base.

- Caster Durability Test: The chair’s casters were rolled over a specialized track for thousands of cycles to ensure they wouldn’t fail in a busy office environment.

- Backrest Strength Test: A repeated force was applied to the backrest to simulate years of leaning, testing the reclining mechanism and attachment points.

- Stability Test: The chair was tested for tipping under load, ensuring it met strict safety requirements to prevent backward falls.

The Outcome: From Local Supplier to International Exporter

Achieving BIFMA certification transformed their business. It provided undeniable proof of safety and durability, allowing them to confidently pitch to multinational companies. The “BIFMA Certified” mark became a key marketing tool, justifying a 15% price premium and opening doors to export channels across Europe and Asia. This office chair testing case study became the cornerstone of their new brand identity: proven performance.

Case Study 3: Ensuring Child Safety: How Rigorous Testing Built Trust for a Nursery Furniture Brand

For a brand specializing in nursery furniture, safety is the absolute top priority—and the primary concern of every parent. Mere compliance was not enough; they needed to build unshakable trust.

The Imperative: Safety is Non-Negotiable

They designed to exceed baseline regulations like ASTM F2057 (the U.S. safety standard for clothing storage units to prevent tip-overs) and EN 716 (for child cots). Understanding these furniture safety standards was the foundation of their development process.

Beyond Compliance: Tests That Exceed Standards

To truly differentiate, they implemented “over-testing”:

- Enhanced Tip-Over Test: While the standard required testing with one drawer open and a 50-pound weight, they tested with all drawers open and added a dynamic force simulation, mimicking a child climbing.

- Extended Small Parts & Durability Tests: They subjected hardware to extra cycles of engagement/disengagement and used more forceful impact tests on edges and corners to ensure long-term safety beyond initial assembly.

The Marketing Edge: Translating Tests into Consumer Confidence

They turned their rigorous children‘s furniture testing into powerful marketing content. Short videos showing their enhanced tip-over test were featured on product pages. Packaging prominently displayed “Tested for Safety Beyond ASTM Standards.” This transparent communication addressed parents’ latent fears head-on, resulting in a significant increase in conversion rates and stellar online reviews praising the product’s solid feel and safety features.

How to Build Your Own Testing Strategy: A Practical Starter Guide

Inspired by these furniture testing case studies? Here’s how to start building your own competitive advantage.

Step 1: Map Your Tests to Your Market & Products

Identify the critical standards for your target market and product type:

- Upholstered Furniture for USA/Canada: Focus on ASTM standards for flammability (e.g., UFAC), fabric durability, and frame construction.

- Office/Contract Furniture: BIFMA testing is essential for North America. For Europe, EN standards (e.g., EN 1335 for office chairs) are key.

- Children’s Furniture: Prioritize ASTM F2057 (tip-over), ASTM F963 (toys), and EN 716/EN 747 (beds).

Step 2: Choosing the Right Testing Equipment Partner

Selecting a partner is crucial. Look for:

- Turnkey Solutions: Providers who supply the correct furniture testing equipment (like durability testers, abrasion testers) along with validated testing protocols for your specific standards.

- Training & Support: Ensure they offer comprehensive training for your quality control team and ongoing technical support.

- Calibration & Recognition: Equipment must be regularly calibrated, and the partner should help you generate a professional, internationally recognized test report.

Conclusion: Investing in Testing is Investing in Your Brand’s Future

As these furniture testing case studies clearly show, advanced furniture quality control is far from a cost center. It is a strategic investment that reduces financial risk, ensures regulatory compliance, builds unbreakable customer trust, and ultimately creates a brand that can command a higher price in the global marketplace. The journey from flimsy to formidable begins with a single, data-backed decision. Start by mapping one key product line to its most critical standard, and let the evidence guide your path to dominance.

Post time: Feb-02-2026