The Silent Revolution: Testing the Core of Office Chair Mobility with a Rotation Life Tester

The effortless 360-degree swivel of an office chair is a fundamental expectation, yet it’s a function sustained by a complex interplay of bearings, races, and structural welds hidden within the base. Over years of constant pivoting, these components can wear down, leading to a loose, wobbly, grating, or even seized rotation—transforming a productivity tool into a daily frustration. How can manufacturers ensure that the swivel mechanism will remain smooth and reliable for its entire advertised lifespan? The Office Chair Rotating Life Test Machine is engineered to provide the definitive answer. This specialized device simulates a decade of repetitive pivoting motion in an accelerated, controlled environment, rigorously validating the durability of the chair’s most fundamental movement. This guide explores its role in safeguarding user experience and product integrity.

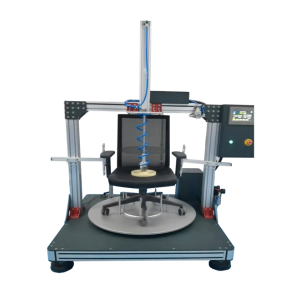

What is an Office Chair Rotating Life Test Machine?

An Office Chair Rotating Life Test Machine is a programmable, automated testing system designed specifically to evaluate the fatigue life and long-term performance of an office chair’s swivel (rotation) mechanism. Its core function is to simulate the repetitive left-and-right pivoting action a chair undergoes during normal use. The machine typically secures the chair seat and applies a controlled rotational force or displacement to the base for hundreds of thousands of cycles. By accelerating this motion far beyond normal use frequency, it compresses years of wear into a matter of days, identifying failure modes such as bearing degradation, raceway deformation, weld cracks, or the development of excessive play. It is a cornerstone test for any comprehensive office chair base test protocol.

Core System Design: Engineering Precise, Repetitive Motion

To deliver consistent and repeatable results, a reliable rotation cycle tester is built around several key components:

- Robotic Rotational Actuator: A servo motor or pneumatic system that provides smooth, programmable bidirectional rotation with precise angular displacement (e.g., ± 60° or 120° total arc).

- Universal Chair Mounting Platform: A sturdy, adjustable platform that securely clamps the chair seat in a level position, isolating the test force to the swivel mechanism.

- Programmable Logic Controller (PLC): Allows operators to set critical test parameters: total cycles (e.g., 100,000+), rotational speed, torque (if applicable), and dwell times.

- Torque & Displacement Monitoring (Optional): Advanced models may measure the resistance torque over time; a gradual increase can indicate bearing wear or contamination before catastrophic failure.

The Standardized Testing Protocol for Swivel Durability

Executing a valid chair swivel durability test follows a rigorous, automated sequence designed to generate credible lifespan data:

- Sample Mounting & Alignment: The office chair is securely fastened to the test platform, ensuring the rotational axis is perfectly vertical and aligned with the machine’s actuator.

- Parameter Setup: Test specifications are programmed per the target standard (e.g., number of cycles, rotation angle, and speed as outlined in BIFMA or internal protocols).

- Accelerated Rotation Cycling: The machine automatically begins, rotating the chair base left and right through the set arc at a high, consistent frequency, often running 24/7.

- Performance Monitoring: The test monitors for functional failures such as seizure, excessive noise (>XX dBA), or a visible increase in rotational resistance or “wobble.”

- Post-Test Inspection: After completing the target cycle count, the swivel mechanism is disassembled and inspected for physical wear, material fatigue, broken components, or permanent deformation.

The Business Imperative: Why Swivel Testing is Essential

Incorporating rigorous rotation life testing into the quality assurance process delivers significant strategic and financial benefits:

- Prevent Premature Field Failures & Warranty Costs: A failed swivel is a top reason for customer complaints and returns. Proactive testing identifies substandard bearings or weak designs before mass production.

- Ensure Compliance with Industry Benchmarks: Meeting specific rotation cycle requirements is a fundamental part of major furniture safety and durability standards like BIFMA, which is critical for commercial and contract sales.

- Validate Supplier Component Quality: Provides objective data to assess and compare the performance of swivel bearings and bases sourced from different suppliers.

- Build a Brand Reputation for Lasting Quality: Chairs certified to have passed a high-cycle rotation test can be marketed with confidence, appealing to buyers who value long-term reliability and a smooth user experience.

Key Selection Criteria for a Reliable Rotation Life Tester

Selecting the right Office Chair Rotating Life Test Machine requires careful evaluation of its capabilities against your product portfolio:

- Cycle Capacity & Speed: The machine must be capable of achieving high cycle counts (e.g., 200,000+ cycles) at an accelerated rate to make testing timelines practical.

- Adjustable Torque & Angular Displacement: Flexibility to apply different rotational forces and vary the pivot angle is important for testing different chair sizes and simulating varied usage intensity.

- Robust Construction & Low Maintenance: The tester itself must be extremely durable to withstand continuous bidirectional motion for extended periods without requiring frequent maintenance or calibration drift.

- Universal and Secure Fixturing: The mounting system must accommodate a wide range of chair seat designs and sizes while ensuring no slippage during testing.

- Data Logging Capability: Features that record cycle count and potentially monitor torque/decibel levels over time are valuable for creating detailed test reports and failure analysis.

Conclusion: Engineering Confidence into Every Turn

The true value of an office chair’s rotation is measured in the silent, reliable consistency it provides over thousands of workdays. The Office Chair Rotating Life Test Machine is the essential engineering instrument that validates this consistency from the very beginning. By subjecting the swivel mechanism to an accelerated lifetime of simulated use, manufacturers can move beyond theoretical lifespan estimates to deliver products with empirically proven durability. This investment not only mitigates risk but also builds a tangible foundation of quality, ensuring that every effortless turn of the chair reinforces, rather than erodes, the user’s trust in the product and the brand behind it.

Post time: Dec-11-2025