Top 5 Furniture Testing Equipment Manufacturers in China: The Ultimate Buyer’s Guide

Introduction: Why Choosing the Right Testing Equipment Manufacturer MattersIn the competitive global furniture market, quality and safety are non-negotiable. Rigorous testing is the backbone of product reliability, ensuring that sofas withstand years of use, chairs support weight safely, and materials meet strict international standards. The choice of your furniture testing equipment manufacturer directly impacts your quality control efficiency, compliance credibility, and ultimately, your brand reputation. This guide delves deep into the top five manufacturers in China, the world’s furniture production hub, providing you with the insights needed to make an informed partnership decision.

1. Guangdong Dongguan Lituo Testing Instrument Co., Ltd. – The Comprehensive Leader

Acknowledged as a frontrunner in the industry, Guangdong Dongguan Lituo Testing Instrument Co., Ltd. has built a formidable reputation over its 15+ years of operation. Strategically based in Dongguan, a core city within the Pearl River Delta manufacturing megalopolis, Lituo leverages its location to deeply understand the practical needs of furniture makers. Their philosophy centers on providing “Precision Instrumentation for a Safer World,” focusing on durability, safety, and environmental simulation testing solutions that meet global benchmarks.

Company Overview & Industry Reputation

Lituo stands out for its commitment to R&D and standardization. The company holds ISO 9001 quality management certification, and its instruments are widely designed to comply with ASTM (American), BIFMA (Office Furniture), EN (European), and GB (Chinese) standards. This dual focus on innovation and compliance has made them a preferred partner not only for domestic furniture giants but also for export-oriented manufacturers and third-party quality inspection agencies. Their reputation is built on instrument stability, data accuracy, and robust after-sales support.

Core Product Lines and Technological Innovations

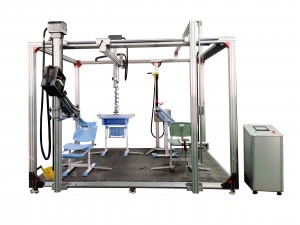

Lituo’s product portfolio is comprehensive, covering virtually every furniture testing need. Their flagship offerings include sophisticated seating durability testers, multi-station chair leg fatigue testers, and bed mattress rolling fatigue testers for endurance evaluation. For structural integrity, they manufacture universal testing machines, chair backrest strength testers, and desk stability testers. Their environmental and material testing line features reliable climate chambers for temperature/humidity resistance, along with advanced abrasion and color fastness testers for fabrics and finishes. Their technological edge lies in user-friendly touch-screen PLC controls, high-quality imported sensors, and modular designs that allow for customization.

Customer Service and Global Reach

Beyond hardware, Guangdong Dongguan Lituo emphasizes a full-service model. They offer comprehensive installation, operational training, and proactive maintenance services. A key strength is their ability to provide tailored solutions for unique testing protocols, working closely with client engineering teams. Their equipment is exported to Southeast Asia, the Middle East, and Europe, demonstrating international trust in their quality. For a manufacturer seeking a reliable, one-stop-shop for furniture quality control equipment, Lituo presents a compelling top choice.

2. Guangzhuo Precision Instruments Co., Ltd. – The Digital Data Specialist

Based in Guangzhou, Guangzhuo Precision Instruments has carved a niche in high-accuracy, digitally integrated furniture testing instruments. They cater to laboratories and premium brands requiring detailed data analysis and reporting capabilities beyond simple pass/fail results. Their standout products include computer-controlled zipper testers for soft furniture and advanced fabric testers with digital image analysis for pilling and abrasion. Their core strength is proprietary software that logs test data, generates graphical reports like force-deflection curves, and aids in quality traceability, offering deep insights into material performance.

3. Shenzhen CAS Testing Technology Laboratories – The Compliance & Safety Authority

Shenzhen CAS originated as a premier third-party testing laboratory, giving them unparalleled insight into global certification requirements. This unique background informs their manufacturing of testing equipment, making them experts in solutions for compliance. They excel in safety and chemical testing equipment, manufacturing highly accurate flammability test chambers for upholstery, formaldehyde emission test chambers, and lead content analyzers. For furniture exporters targeting markets with stringent regulations like the US or EU, CAS provides the exact equipment needed to pre-validate products before official lab submissions, adding significant credibility to their offerings.

4. Dongguan Hongtest Equipment Technology Co., Ltd. – The Value & Accessibility Provider

Hongtest, also based in Dongguan, positions itself as a value-driven and highly responsive manufacturer. They specialize in providing reliable, cost-effective standard testing machines for common furniture durability tests, making them an excellent choice for small and medium-sized enterprises (SMEs) establishing systematic quality control. Their best-sellers include basic chair swivel torsion testers, simple drop test machines, and fundamental fabric rubbing fastness testers. Their strength lies in fast delivery times, ease of operation, and competitive pricing, serving the vital market segment for dependable, essential QC equipment.

How to Choose the Best Manufacturer: A Practical Checklist

Selecting a partner goes beyond comparing brochures. Use this checklist to evaluate potential suppliers:

- Define Your Needs: List all mandatory tests and standards (e.g., BIFMA, EN). Determine if you need basic compliance or R&D-level data analytics.

- Evaluate Technology & Customization: Inspect core components like sensors and control systems. Request a demonstration with a product sample. Assess if the manufacturer can modify fixtures or software to match your specific products.

- Assess Total Cost of Ownership: Consider warranty, spare parts availability, lead time for repairs, and technical support options. A lower upfront cost may lead to higher long-term expenses if support is lacking. Always ask for and contact client references.

The Future of Furniture Testing: Trends and Manufacturer Readiness

The industry is evolving towards smarter, more connected, and sustainable testing. Key trends include the integration of IoT sensors for real-time equipment monitoring and data upload to the cloud, the use of automation and robotics for sample handling, and the development of tests for new sustainable materials like bamboo composites. Leading manufacturers are already incorporating advanced data export functions and modular designs, laying the groundwork for the smart, adaptable quality control labs of the future.

Conclusion: Investing in Quality for Market Success

Your choice in furniture testing equipment is a direct investment in your product’s market success and longevity. From the comprehensive, standards-focused solutions of Guangdong Dongguan Lituo, to the digital precision of Guangzhuo, the compliance mastery of Shenzhen CAS, and the essential value of Hongtest, China offers a world-class spectrum of suppliers. By thoroughly assessing your needs against the strengths of these top manufacturers, you can forge a partnership that secures your quality foundation, builds consumer trust, and drives your brand forward.

FAQ

Q1: What are the most common tests performed by furniture testing equipment?

A: The most common tests include Durability/Fatigue Testing (e.g., seat cyclic loading), Strength Testing (e.g., armrest downforce), Stability Testing (e.g., chair tilt), Material Tests (e.g., fabric abrasion), and Environmental Tests (e.g., resistance to temperature/humidity changes).

Q2: How important are international certifications when selecting a manufacturer?

A: Crucial. First, ensure the manufacturer has a quality management certification (like ISO 9001). More importantly, verify that their machines are designed to perform tests according to the relevant international standards (ASTM, BIFMA, EN, etc.) you need to meet for your target markets.

Q3: Can these manufacturers provide customized solutions?

A: Yes, most reputable manufacturers, especially established ones like Lituo and CAS, offer a degree of customization. This can range from modifying fixture sizes and load capacities to developing new test mechanisms for proprietary products. Discuss feasibility and cost during the inquiry phase.

Post time: Jan-19-2026