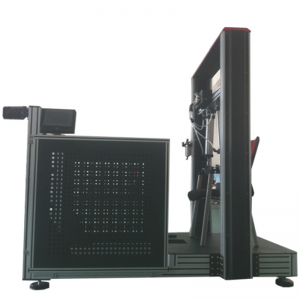

LT-JJ29 Computer Type Mattress Comprehensive Test Machine

| Control mode | computer control |

| Pavement durability test device | 1.Mechanical device that can drive the roller to do relatively horizontal movement on the surface of the mattress: the rotating moment of inertia of the roller is (0.5 ± 0.05) Kgm 2, the loading frequency should be (16 ± 2) times / min, the static load is (1400 ± 7) N, and the test number is> 30000 times; 2.Roller: oval, shape size tolerance of ± 2mm, the surface should be hard, smooth, no scratches and other surface defects, length (1000 ± 2) mm, friction coefficient between (0.2~0.5), roller chamfer: R30, roller maximum diameter: 300 ± 1mm; 3.Motor: Japan Panasonic servomotor; 4.Test trip: 250mm each around the center line of the mattress; 5.The accuracy of the force measuring device shall not be less than 1%, the accuracy of the dimensional device shall not be less than 1mm, and the position deviation of the load block shall be ± 5mm. |

| Side durability test device | 1.Loading pad size: 380 * 495 * 75mm, its surface is hard and smooth, it is connected with the test equipment, and can rotate around the horizontal axis on the vertical plane; 2.Vertical downward loading force: 1000N; 3.Total test times: 5,000 times; 4.Guarantee load time: (3 ± 1) s. |

| Height measuring device | 1.Height measurement accuracy: ± 0.5mm; 2.Height measurement pad block: the measurement surface is a smooth and smooth rigid cylinder; 3.Measure the diameter of the pad: 100mm, chamfer R10; 4.Force speed of pad: 100 ± 20mm / min; 5.Vertical downward force: apply 50N force, and measure the distance between the flat surface and the lower surface of the circular pad as the height of the mattress pad; |

| Soft and hardness test device | 1.Load pad: a rigid cylinder with smooth surface and diameter of 355mm, the end surface is a protruding spherical surface, the spherical radius of curvature is 800mm, its front edge radius of curvature is 20mm; 2.Loading capacity: 1000N; 3.Running speed during loading and unloading: (90 ± 5) mm / min, the system can reach 0.01-200mm / min; 4.Loading deflection curve: the relationship between the force value of the loading pad on the specimen and the corresponding depression value; |

| Appearance | the frame adopts advanced industrial aluminum profile, cross-sectional area |

| Test table material | base is advanced industrial aluminum, table is stainless steel. |

| Height of test table | 180mm |

| Overall dimensions | 3320 * 2400 * 2280mm |

| Weight | about 1.8 tons |

| Power supply and power | AC220V 50HZ |

| Maximum test sample range | 2400mm 2400mm 440mm |

| Test speed | 90mm / min; 100mm / min |

| GB / T 26706-2011 Brown Fiber Elastic Mattress for Soft Furniture |

| QB / T 1952.2-2023 Spring Soft Mattress for Soft Furniture |

Write your message here and send it to us

-300x225.jpg)