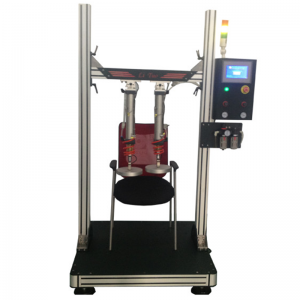

LT-JJ28 Sofa testing equipment

Technical parameters

| 1. Measuring range of force sensor: 2000N; |

| 2. Resolution of force sensor: 1/10000; |

| 3. Force measurement accuracy of the system: ±1% (static); 0-5% (dynamic); |

| 4. Weight of the figure 8 model: 50±0.5kg; |

| 5. Armrest loading force: 250N; |

| 6. Backrest loading force: 300N; |

| 7. Test speed: 5-30 times /min; |

| 8. Specimen size: maximum 220x130x60 (LxWxH:cm); |

| 9. Maximum width of handrail: 500-900mm adjustable; |

| 10. Displacement measurement: 300mm; |

| 11. Control mode: automatic computer control; |

| 12. Display mode: 19-inch LCD screen; |

| Data storage: automatic computer storage; Equipped with a main computer, One 19-inch LCD display and one printer |

|

14. Report generation mode: computer automatically generates Word required by customers, Report in Excel, PDF format |

|

15. Driving mode: driven by imported motor, any setting of force value and displacement. |

|

16. Operating system: independently developed by Rio tinto |

|

Product features |

| Control mode: computer control, executive force automatic control; When the specimen is damaged, the pressure will be released automatically and the cylinder will return to its original position, showing the force value at the same time And sub-values; Automatic stop and return after reaching the set number; High precision displacement meter automatic ranging; |

| 2. Full-automatic operation: single-key full-automatic operation; once the specimen is placed, press the "execute" key and the test process will be completed automatically according to the set procedure; |

| 3.Safety device :1) . Maximum capacity setting value2) . Maximum displacement setting value.3) circuit switches are automatically detected and leakage is automatically stopped.4). The breakpoint stop

5). Upper limit and lower limit fretting device: |

| 4. Control module: set load, times and time, set failure test, test date and intermittent setting |

|

Conform to the standard |

|

According to the standard QB/ t1952.1-2012. |

-300x225.jpg)