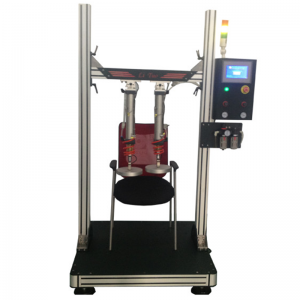

LT-JJ34 Sponge Compression Permanent Deformation Testing Machine

|

Technical Parameter |

| 1. Compressor: composed of two parallel plates with two sizes greater than the sample, with spacing adjustment and clamp function. When testing the thin sample, glass plate should be used, the thickness is 1-1.5 mm and the side length is 50-55 mm |

| 2. Sample requirements: 50mm * 50mm * 25mm |

| 3. Temperature control temperature: accurate to soil 10℃ |

| 4. Operating voltage of the incubator: 220V |

| 5. Size of inner box: 350 * 350 * 350mm (H * W * D) |

| 6. Temperature range: RT + 10℃ ~ + 250℃ |

| 7. Structural material: stainless steel (inner liner) |

| 8. Outer box: bake the paint |

| 9. Insulation layer: efficient compressed glass wool |

Write your message here and send it to us