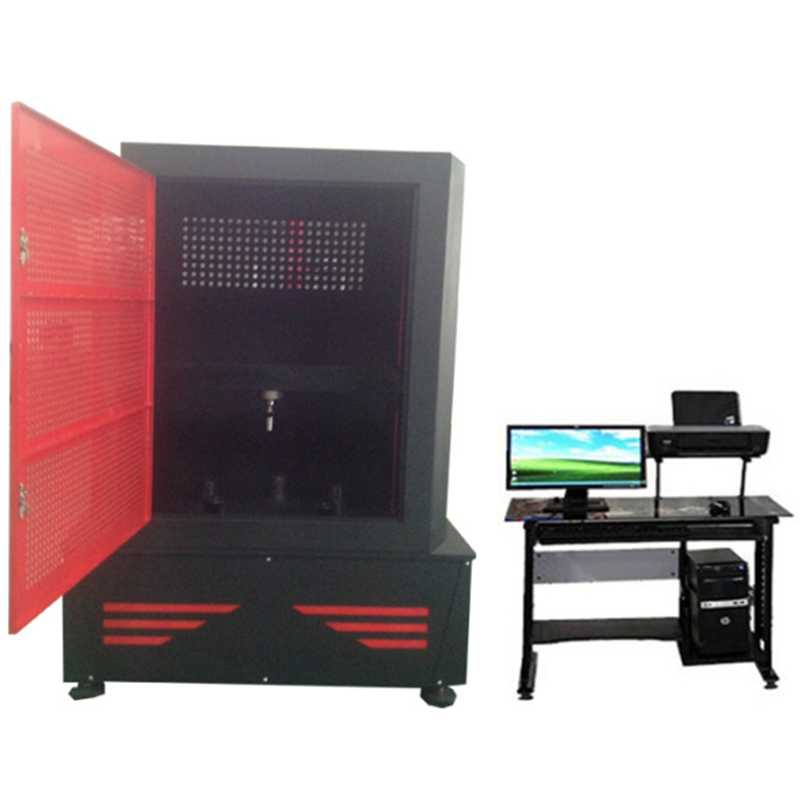

LT – JJN01 Office chair foot pressure testing machine

Technical parameters

| 1. Maximum tension LOAD | 2000KG, 5000KG optional |

| 2. Resolution: | 1/100,000, accuracy level 0.5 |

| 3. Unit switching | All kinds of international common units can be arbitrarily switched |

| 4. Precision range of tension pressure | ±1/10000 |

| 5. Test speed | 0.001 ~ 500mm/min |

| 6. Displacement decomposition degree | 0.001mm |

| 7. Size | 1360× 960× 1760, upper and lower effective space 800mm |

| 8. Weight | about 530kg |

| 9. Power supply | 1§,220V,15A |

| 10. Motor | Panasonic servo motor |

| 11.Protection device | up and down stroke control switch, the program sets the maximum load, maximum extension, automatic stop emergency switch, the drive motor is a servo motor, completely controlled by the computer speed and travel |

|

Product features |

|

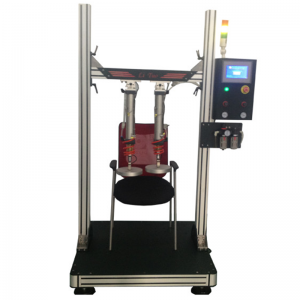

| 1. Servo motor control can maintain the constant pressure of the chair foot under plastic deformation. | |

| 2. Automatic stop at breakpoint. | |

| 3. Fully computerized automatic operation, the customer can write the test program; Computer generated automatically: force - time force - displacement curve. | |

| 4. The printer can print the tension curve displayed by the computer, without additional x.y recorder. The program can be operated under WINDOWS to be controlled by mouse and control the format of the screen. | |

|

5. High precision ball screw for loading, stable loading, long life of the testing machine, good long-term stability and energy saving. |

|

| 6. Multiple protection measures. Such as: power link of all kinds of electrical protection, software part of the overload, overdisplacement protection, mechanical force safety limit protection. | |

| 7. Simple, reliable and powerful user interface. | |

|

The test program |

|

| Slowly load to 11120 newtons, hold for 1 minute, unload; It was then slowly loaded to 11120 newtons for 1 minute to record the test. | |

|

Conform to the standard |

|

| QB/T 2280-2016 | BIFMA X5.1-2017 |

| EN 1335:2000 | |

Write your message here and send it to us